Best Welded Wire Mesh Uses and Benefits Explained?

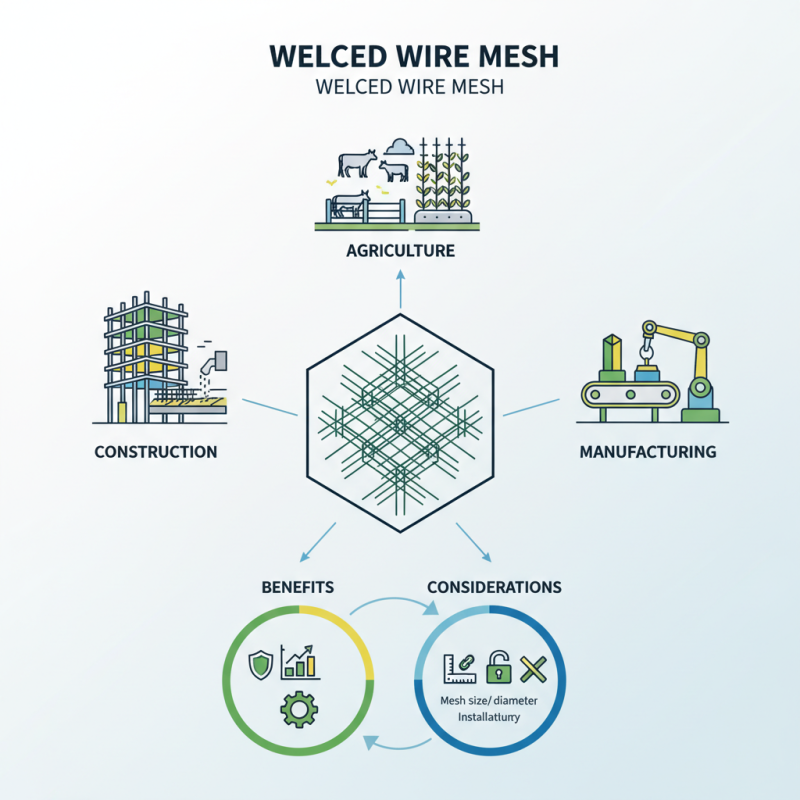

welded wire mesh has gained increasing acclaim for its versatility and strength. This material is used across various industries, including construction, agriculture, and manufacturing. According to a recent report by MarketsandMarkets, the global welded wire mesh market is expected to reach approximately $6.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.2%. This data highlights the growing reliance on welded wire mesh, particularly in developing nations where infrastructure projects are booming.

In construction, it serves as a critical reinforcement element. It enhances concrete structures, providing durability and support. Welding techniques ensure consistent spacing, which minimizes weak points in construction materials. However, not all applications benefit equally. The choice of wire diameter and mesh size is crucial. Miscalculations can lead to structural failures. In agriculture, welded wire mesh secures livestock and supports gardens. Yet, improper installation may lead to animal escapes or crop damage.

These examples illustrate both the advantages and challenges of using welded wire mesh. When applied properly, it delivers unmatched reliability. However, attention to detail is essential to maximize its potential. A careful approach can lead to improved safety and efficiency in various applications.

Best Welded Wire Mesh Applications in Residential Construction

Welded wire mesh plays a vital role in residential construction. It provides structural support and offers various benefits. This mesh is typically made from steel wires, which are welded together to form a grid. According to industry studies, around 30% of construction projects incorporate welded wire mesh to improve stability.

In foundations, welded wire mesh reinforces concrete, enhancing its tensile strength. This means less cracking over time. In wall systems, it acts as a barrier against pests. In fact, many reports suggest that using mesh can reduce pest issues by up to 25%. This makes homes not only safer but also more durable.

However, challenges exist. Not every mesh type is suitable for every project. Selecting the right gauge and spacing can be tricky. Miscalculating these factors can lead to structural failures. As professionals often note, understanding the specific needs of a project is crucial. Residential builders must carefully assess their requirements to ensure long-term satisfaction.

Best Welded Wire Mesh Uses and Benefits Explained

| Application | Description | Benefits |

|---|---|---|

| Fencing | Used for residential, commercial, and agricultural fencing. | Durable, minimal maintenance, provides visibility. |

| Concrete Reinforcement | Incorporated into concrete slabs and walls to enhance strength. | Improves load-bearing capacity and reduces cracking. |

| Garden Trellises | Used to support climbing plants in gardens. | Lightweight, flexible design, enhances aesthetics. |

| Animal Enclosures | Creates secure living spaces for pets and livestock. | Safe, sturdy, and effective at keeping animals in/out. |

| Security Screens | Installed on windows and doors for added protection. | Increases security without obstructing views. |

Key Benefits of Using Welded Wire Mesh in Agricultural Settings

Welded wire mesh plays a crucial role in agricultural settings. Its strength and durability make it ideal for various applications. Farmers appreciate its versatility for fencing, reinforcing structures, and creating livestock enclosures. According to industry reports, the global market for welded wire mesh is expected to reach $4 billion by 2025, driven by the agricultural sector's growing needs.

One significant benefit of using welded wire mesh is its cost-effectiveness. Farmers can reduce expenses by using this material for long-lasting solutions. For example, a well-maintained welded wire fence can last up to 30 years, compared to wood, which may need replacing every decade. Furthermore, welded wire mesh provides excellent visibility and airflow, which benefit crop health. These factors contribute to increased productivity.

Yet, some challenges persist. Not all welded wire meshes are created equal. Farmers must select the right gauge and coating to prevent rusting. Some may find that low-quality options lead to quicker wear and require frequent replacements. This can be a concern in high-humidity areas. Awareness of these details is vital to ensure the longevity of welded wire mesh in agriculture.

Comparative Analysis: Welded Wire Mesh vs. Other Fencing Materials

Welded wire mesh stands out when compared to alternatives like chain link or wooden fences. Its durability makes it ideal for various applications. Unlike wood, which can rot, welded wire mesh resists weather elements. It's also less prone to corrosion than chain link fences when made with proper materials. This means less frequent replacements and maintenance.

However, aesthetics can be an issue. Some find welded wire mesh less appealing visually. It lacks the traditional charm of wood fencing. This can deter homeowners who prioritize looks over functionality. Cost is another factor. While initially affordable, installation and potential modifications can add up. This requires thinking ahead before choosing material.

In terms of security, welded wire mesh provides excellent visibility while maintaining strength. Unlike wood or vinyl, it does not obstruct sight lines. This can be beneficial for surveillance but doesn't guarantee privacy. People may want to consider their specific needs carefully. Balancing visibility and security can lead to thoughtful choices.

Industry Standards and Regulations for Welded Wire Mesh Production

Welded wire mesh plays a crucial role in various industries, primarily due to its structural integrity and versatility. Industry standards and regulations guide its production to ensure safety and quality. For instance, ASTM A185 outlines the specifications for plain and welded wire fabric. Adhering to these standards is essential in construction applications, where proper load-bearing capabilities are required.

Manufacturers must also comply with ISO 9001, which sets forth quality management principles. This certification emphasizes a unified approach to quality assurance, impacting the durability and performance of welded wire mesh. Regular audits and inspections maintain these high standards throughout the production process. Compliance can increase customer trust and brand loyalty.

However, not all manufacturers consistently follow these regulations. Some businesses may cut corners, leading to subpar materials that do not meet safety requirements. Consequently, consumers must be vigilant. Understanding the fundamental regulations in place can help ensure that the welded wire mesh they purchase is reliable and safe. Always question the origin and compliance of materials.

Cost-Effectiveness and Longevity of Welded Wire Mesh Solutions

Welded wire mesh offers significant cost-effectiveness in various applications. Its structure provides a strong barrier while maintaining affordability. The mesh is created by precision welding, which enhances its stability and strength. This durability means fewer repairs or replacements are needed over time. An upfront investment in welded wire can lead to long-term savings.

Longevity is another key benefit. High-quality welded wire mesh resists rust and corrosion. This resilience is crucial in outdoor and industrial environments. While weather extremes can pose a challenge, proper coating can extend the mesh's lifespan even further. However, not all coatings perform equally. It’s essential to choose wisely.

One must also consider installation costs. While the material itself may be affordable, labor costs can vary significantly. Installing the mesh requires skill to ensure its effectiveness. Mistakes during installation can lead to wasted materials and additional expenses. Therefore, investing in a seasoned professional is always wise.