The Ultimate Guide to Choosing the Best Fibre Optic Cable Ducting Solutions

In an era where high-speed internet connectivity is a necessity rather than a luxury, the importance of selecting the appropriate fibre optic cable ducting solutions cannot be overstated. With the global fibre optic cable market projected to reach $11.5 billion by 2026, the demand for efficient and reliable ducting systems is surging. According to a recent market analysis by Research and Markets, the increasing need for enhanced bandwidth and improved network infrastructure is driving innovation in cable management solutions. As the telecommunications industry evolves, professionals are turning to advanced fibre optic cable ducting to meet their growing demands.

Expert in the field, Dr. Emily Hart, a leading voice in telecommunications infrastructure, emphasizes the critical role of smart ducting solutions. She states, "The right fibre optic cable ducting not only ensures the integrity of the network but also enhances the scalability and future-proofing of communications systems." By prioritizing proper ducting installations, organizations can better armor their networks against physical damage and environmental factors, ultimately contributing to long-term efficiency and cost savings. As we explore the options available in this comprehensive guide, it is essential to consider the fundamental aspects that lead to optimal fibre optic cable ducting solutions tailored to meet specific project requirements.

Key Factors to Consider When Choosing Fibre Optic Cable Ducting

When selecting fibre optic cable ducting solutions, several key factors must be considered to ensure optimal performance and safety. The global market for submarine fibre optic cables is projected to reach approximately $320.68 million by 2024, with an expected growth to $341.25 million in 2025, ultimately rising to around $486.93 million by 2032. This trajectory underscores the importance of investing in robust ducting systems that can adequately protect these critical infrastructures from environmental and security threats.

One crucial factor to evaluate is the duct material, which influences durability and resistance to external damage. Ducts made from high-quality, UV-resistant materials are essential for withstanding harsh oceanic conditions and minimizing the risk of physical wear over time. In addition, the design of the ducting system should facilitate easy installation and maintenance, as well as accommodate the specific requirements of the fibre optic cables it houses. Moreover, as submarine communications networks become increasingly vital in global intelligence operations, the chosen ducting solutions must also incorporate measures to mitigate security risks, ensuring the integrity of the data transmitted through these underwater systems.

The Ultimate Guide to Choosing the Best Fibre Optic Cable Ducting Solutions - Key Factors to Consider When Choosing Fibre Optic Cable Ducting

| Feature | Description | Importance Level | Considerations |

|---|---|---|---|

| Material | Common materials include PVC, HDPE, and metal. | High | Choose based on environment conditions and durability needs. |

| Size | Available in various sizes based on cable capacity. | Medium | Ensure it's compatible with existing infrastructure. |

| Temperature Resistance | Rated for various temperature extremes. | High | Determine based on installation location. |

| UV Resistance | Protection against sunlight exposure. | Medium | Essential for outdoor installations. |

| Fire Rating | Resistance to flame spread. | High | Compliance with safety regulations is crucial. |

| Installation Ease | Ease of installation and handling. | Medium | Look for options that simplify the installation process. |

| Cost | Initial investment versus long-term value. | High | Balance cost with features and durability. |

Types of Fibre Optic Cable Ducting and Their Applications

When it comes to fibre optic cable ducting, understanding the various types available is essential for any installation project. The most common types include indoor ducts, outdoor ducts, and heavy-duty ducts. Indoor ducts are typically designed for internal building use, providing a streamlined pathway for cables while protecting them from environmental factors. These ducts often feature flexible materials that accommodate installations in tight spaces and complex layouts.

Outdoor ducts, on the other hand, are built to endure harsh weather conditions. They typically have robust materials that resist moisture, UV radiation, and extreme temperatures, ensuring the integrity of the fibre optic cables over time. Heavy-duty ducts offer additional protection and are ideal for industrial applications where cables may be exposed to physical stress or environmental hazards. Understanding these options helps in selecting the right ducting solution based on the specific requirements of each application, ensuring optimal performance and longevity of the network infrastructure.

Installation Guidelines for Fibre Optic Cable Ducting Solutions

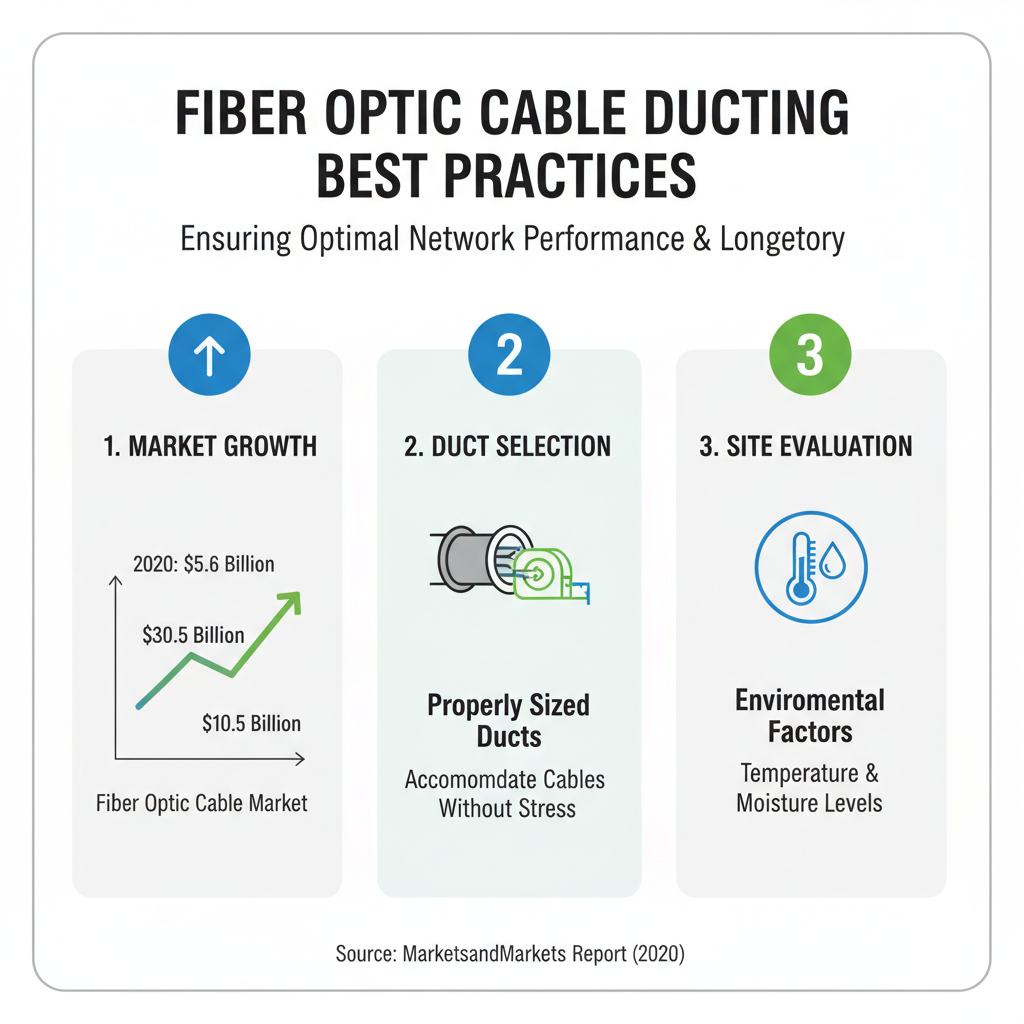

When installing fibre optic cable ducting solutions, adherence to best practices is essential to ensure optimal performance and longevity of the network. According to a report by MarketsandMarkets, the fibre optic cables market is expected to grow from USD 5.6 billion in 2020 to USD 10.5 billion by 2025, emphasizing the increasing demand for robust installation techniques. Properly sized ducts must be selected to accommodate the cables without putting undue stress on them. The installation site should also be evaluated for environmental factors such as temperature fluctuations and moisture levels that could impact cable performance.

**Tip:** Always plan your duct routing carefully to avoid sharp bends and tight corners, which can lead to signal degradation. A bend radius of at least ten times the outer diameter of the cable is recommended to maintain signal integrity.

During installation, it is crucial to ensure that all ducts and cables comply with industry standards such as the IEC 60793-1-1 and TIA/EIA-568, which provide guidelines on performance requirements. Incorporating pull strings and proper sealing techniques at joints can enhance accessibility for future maintenance or upgrades.

**Tip:** Consider integrating color-coded ducting systems to streamline the identification process during installation and troubleshooting, significantly reducing downtime and improving overall system reliability.

Maintenance Practices for Long-lasting Fibre Optic Ducting Systems

Maintaining fibre optic ducting systems is crucial for ensuring optimal performance and longevity. Regular inspection and preventive measures can significantly reduce the risk of damage and data loss. According to a report by the Fibre Optic Association (FOA), 80% of failures in fibre optic systems can be attributed to improper handling and maintenance. Therefore, establishing a reliable maintenance routine is essential.

Tip: Schedule routine inspections at least twice a year, focusing on checking for signs of physical damage, ensuring proper sealing, and examining the integrity of connectors. Use moisture detection equipment and regular cleaning of connections to mitigate the risk of signal degradation.

Furthermore, proper environmental controls can enhance the longevity of ducting systems. The International Electrotechnical Commission (IEC) advises maintaining optimal temperature and humidity levels, as extreme conditions can adversely affect the fibre infrastructure. Implementing protective measures such as additional insulation and shielding against external elements can minimize wear over time.

Tip: Consider investing in cable management systems that support airflow and prevent overheating, as studies show that investing 20% more in high-quality management solutions can lead to a 50% reduction in maintenance-related costs over the system's lifespan.

The Ultimate Guide to Choosing the Best Fibre Optic Cable Ducting Solutions

This bar chart displays the durability ratings of various fibre optic ducting solutions. These materials are commonly used in fibre optic installations, reflecting their respective longevity and resilience characteristics.

Cost Considerations and Budgeting for Fibre Optic Ducting Projects

When planning a fibre optic ducting project, cost considerations play a vital role in ensuring the project's success while staying within budget. Initially, it's crucial to assess the specific requirements of your installation, including the scale and complexity of the layout. This allows for a more accurate estimation of the overall costs, including materials, labor, and any additional equipment that may be required. Be sure to factor in potential unexpected expenses by allocating a portion of your budget for contingencies.

Tips: Always compare quotes from multiple suppliers to find the best deals on fibre optic ducting materials. Additionally, consider investing in high-quality ducting solutions upfront, as this can lead to lower maintenance costs in the long run.

Another key aspect is to analyze your project timeline. Delays can incur additional costs, so it's advisable to create a realistic schedule that includes all phases of installation. Efficient project management can minimize downtime and streamline the workflow, ultimately saving money.

Tips: Employ project management tools to track progress and ensure all team members are aligned, which can help avoid costly miscommunication and keep your project on schedule.

Related Posts

-

Understanding Drop Cable Types: A Comprehensive Guide for Fiber Optic Solutions

-

Maximizing Efficiency: How Cable Drops Support Modern Infrastructure and Reduce Downtime by 30%

-

10 Essential Tips for Choosing the Right Fibre Network for Your Home

-

Discover the Benefits of Buying Fibre Optic Cable for Your Home Network

-

Exploring the Future of Connectivity with Aerial Fibre Cable Technology

-

Exploring the Rise of Sustainable Cable Tube Solutions: How Industry Trends Shape Energy Efficiency