What is a loose tube fibre cable and how does it work?

Loose tube fibre cables are essential in modern communication. They serve as the backbone of high-speed internet. Their design allows for flexibility and durability, making them popular in various environments.

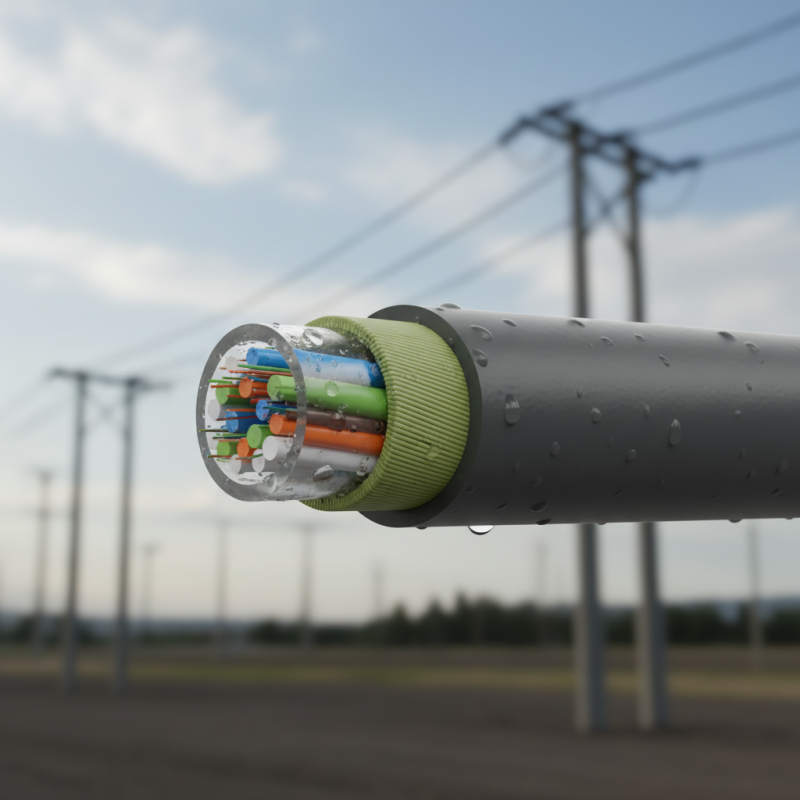

These cables consist of several fibres enclosed in a protective tube. This tube provides space for the fibres to move, reducing stress during temperature changes. Such movement is critical to maintaining performance. Often, these cables are used in outdoor installations. They withstand harsh weather conditions, ensuring reliability.

The unique structure of loose tube fibre cables enables better signal protection. However, installation can be tricky. Proper handling is vital to prevent damage. Understanding these challenges helps technicians work more effectively with this technology. As we explore further, we will uncover the details of how loose tube fibre cables function and their applications.

Definition and Overview of Loose Tube Fibre Cable

Loose tube fibre cable is a popular type of optical fibre cable. It consists of several optical fibres enclosed within a protective tube. This tube is designed to hold the fibres loosely. The loose design allows for greater flexibility and movement, which is crucial during installation.

The internal structure prevents stress on the fibres. This makes loose tube cables highly durable in various environments. Additionally, these cables can accommodate temperature changes and moisture variations. Each fibre is surrounded by a gel or water-blocking material, protecting it from water ingress. This enhances their performance in outdoor settings.

However, working with loose tube fibre cables can be tricky. Installation requires careful handling to avoid damaging the fibres. Misalignment during installation may lead to increased signal loss. Thus, proper training is essential for technicians. Understanding the nuances of loose tube fibres can improve network reliability and efficiency over time.

Components and Structure of Loose Tube Fibre Cable

Loose tube fibre cables are significant in the telecommunications field. They consist of several components that work harmoniously. The outer layer is robust, often made of plastic or gel. This protects fibres from environmental factors. Inside the tube, fibres are loosely placed, allowing for movement. This design helps accommodate thermal expansion and contraction.

The core of each fibre is typically made of glass. This core is surrounded by cladding, which reflects light. Understanding these components is vital. Research indicates that loose tube cables can withstand harsh conditions. Reports show they often last over 25 years, making them reliable for long-term use.

Tips: When installing loose tube fibre cables, be mindful of bending. Too much bend can break the fibres. Use bend radius limits provided in guidelines.

Another tip is to consider the number of fibres you may need. Loose tube designs can house multiple fibres. This flexibility allows for future upgrades. Ensure your network can adapt as demands change.

Mechanism of Operation for Loose Tube Fibre Cable

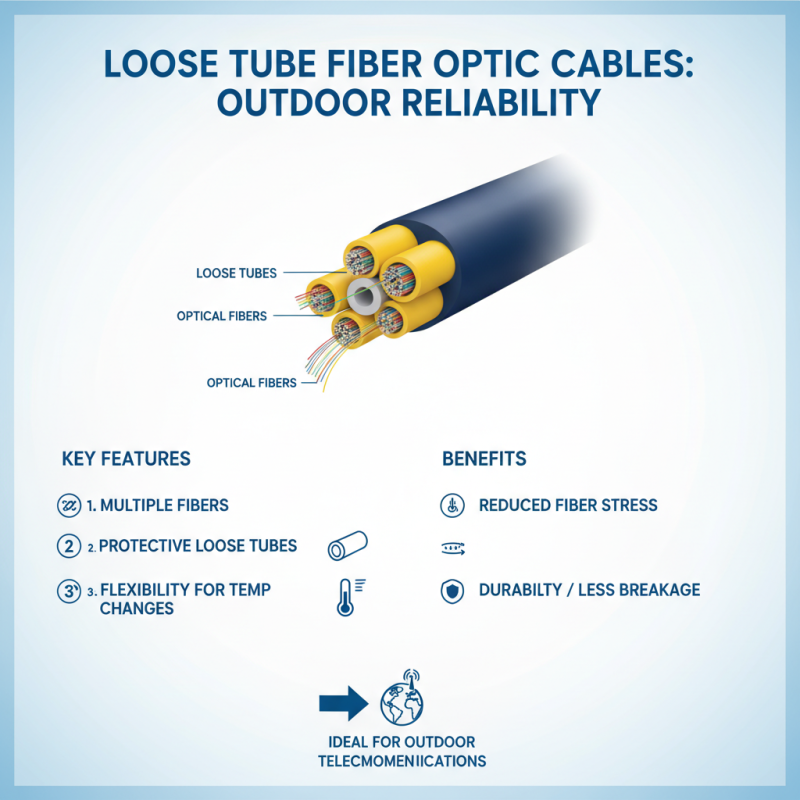

Loose tube fibre cable is an essential component in modern communication systems. Its structure allows for flexibility and protection against environmental factors. The loose tubes contain multiple fibres, which are designed to move freely within the casing. This design reduces stress and allows the fibres to expand and contract without breaking.

The mechanism of operation relies on two main features: buffering and moisture control. The buffer tubes, which hold the optical fibres, are filled with a gel or silicone to protect against moisture. This ensures that the fibres remain safe from water damage. The tubes are not tightly bound, allowing them to accommodate temperature changes. This is important for long-distance communication as it maintains signal integrity over varying conditions.

However, while loose tube cables are robust, they are not impervious to damage. Installation mishaps can lead to compromised cables. Improper handling during installation may introduce microbends that affect signal quality. The cable's performance relies heavily on both proper installation and ongoing maintenance. Users must be vigilant in monitoring the condition of these cables to minimize issues.

Advantages of Using Loose Tube Fibre Cable

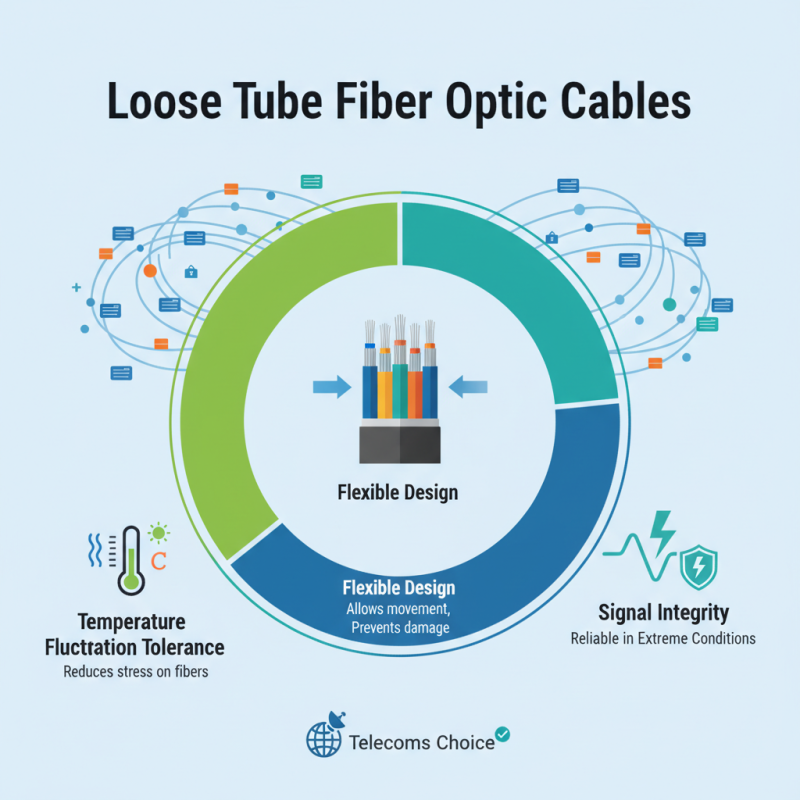

Loose tube fibre cables offer several advantages that make them a popular choice in telecommunications. One significant benefit is their ability to accommodate temperature fluctuations. The loose tube design allows for movement, reducing stress on the fibres during expansion or contraction. This flexibility helps maintain signal integrity even in extreme conditions.

Another advantage is the cable's protection against moisture. Each fibre within the loose tube is surrounded by a gel, which prevents water ingress. This feature is crucial in environments prone to humidity. It safeguards the fibres and ensures long-term performance. Additionally, loose tube cable can be installed in various scenarios, from aerial to underground.

However, there are challenges. Installing loose tube cables may require careful planning. Too much tension during installation can damage the fibres. Maintenance may also be more complex compared to other types. Yet, the benefits often outweigh these issues, making loose tube fibre cables a reliable choice for enhancing communication networks.

Applications and Use Cases for Loose Tube Fibre Cable

Loose tube fibre cables are widely used in telecommunications. Their design makes them ideal for outdoor applications. Typically, these cables contain multiple fibres housed in a loose tube structure. This tube allows for flexibility during temperature changes. As a result, it reduces stress on the fibres, making them less likely to break.

These cables excel in long-distance data transmission. They can handle high bandwidth applications, such as internet and video services. Telecommunications networks often utilize loose tube fibres for backbone installations. Additionally, they are used in urban settings to connect various service points. Their resistance to environmental factors enhances their durability.

In some cases, the installation process can be tricky. Proper handling is crucial to avoid damaging the fibres. Users must be cautious of bends and twists during installation. While loose tube cables are reliable, they require careful planning and execution. They can sometimes be over-engineered for small projects. Recognizing these nuances can aid in making better decisions when selecting cables for specific applications.

Related Posts

-

2026 Best Fibre Drop Cable Options for Reliable Connectivity?

-

What is Fibre Drop Cable and Its Uses in Network Installation

-

Exploring the Future of Connectivity with Aerial Fibre Cable Technology

-

How to Install Aerial Fibre Cable for Faster Internet Connectivity

-

What is Fibre Cable and How Does It Work for Your Connectivity Needs

-

10 Essential Tips for Installing Fibre Optic Ducting Like a Pro