How to Install Fibre Optic Ducting for Optimal Performance?

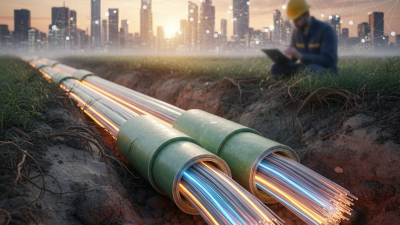

Installing fibre optic ducting is crucial for modern communication networks. Proper installation ensures signal integrity and minimizes data loss. However, many overlook the importance of meticulous planning.

When choosing materials for fibre optic ducting, consider environmental factors. Outdoor installations may require UV-resistant ducts. Indoor ducts need to comply with fire safety regulations. Each choice affects overall performance. A common mistake is neglecting to account for future expansions or changes in technology.

Achieving optimal performance involves precise installation techniques. Ensure proper alignment and secure all joints. This reduces the chance of damage. Regular maintenance checks are essential to avoid unexpected issues. Remember, even the best materials need care. Striking a balance between quality and practicality can be challenging, but it’s necessary for lasting results.

Understanding Fibre Optic Ducting and Its Importance for Performance

Fibre optic ducting plays a vital role in networking performance. It protects cables from physical damage and environmental factors. Proper installation can enhance signal quality and reduce latency. Understanding this ducting's significance helps in planning an effective infrastructure.

Tip: Use high-quality ducting materials to avoid future issues. Investing in robust options pays off in the long run. Avoid the temptation to skimp on materials for cost savings. This can lead to costly repairs later.

Another consideration is the layout. Ensure ducts are not too tight or bunched. Improper spacing can restrict airflow and create heat build-up. This can negatively impact performance. Regularly review the system and identify any potential flaws. Addressing these issues early can prevent bigger problems.

Tip: Document your installation process. This aids in troubleshooting and future upgrades. It’s easy to forget the details over time. Keep records accessible for reference.

How to Install Fibre Optic Ducting for Optimal Performance? - Understanding Fibre Optic Ducting and Its Importance for Performance

| Dimension | Description | Importance | Optimal Material |

|---|---|---|---|

| Duct Diameter | The inner diameter of the ducting | Ensures minimal bending and optimal signal strength | 32 mm |

| Bending Radius | The minimum radius the fibre can be bent | Prevents damage to the fibre and maintains integrity | 10 times the duct diameter |

| Length of Ducting | Total length of ducting required | Directly affects installation efficiency and performance | As per site requirements |

| Environmental Factors | Temperature and moisture levels at installation site | Affects performance and lifespan of the duct | UV resistant materials |

| Sealing Type | Method used to protect the ducting from water ingress | Critical for maintaining signal integrity and moisture protection | Rubber grommets |

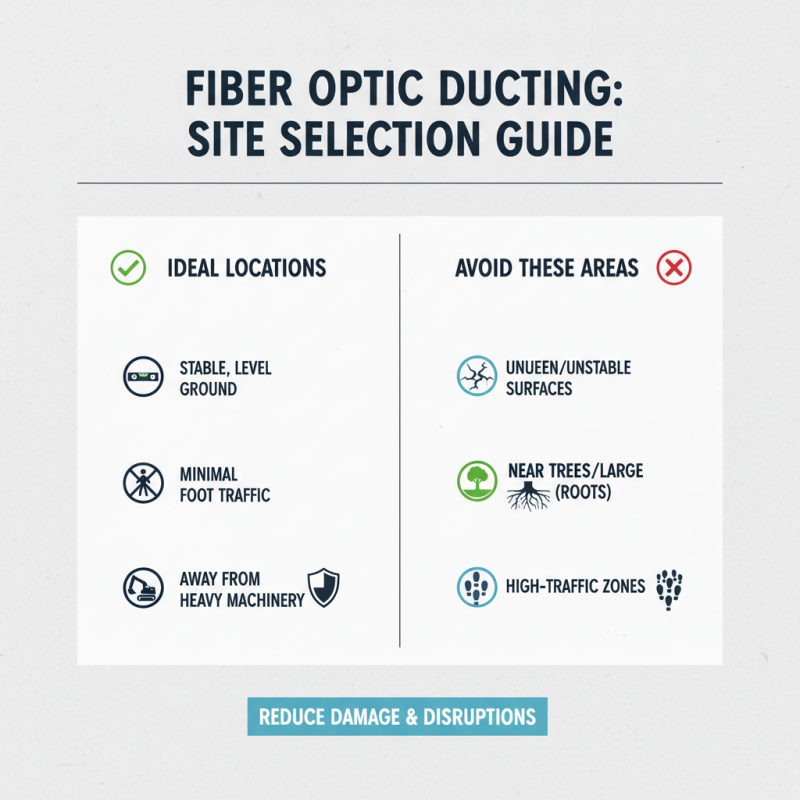

Planning the Installation Site for Fibre Optic Ducting

Choosing the right installation site for fibre optic ducting is crucial. The surface should be stable and level. Consider areas with minimal foot traffic. Look for spots away from heavy machinery. This reduces potential damage to the ducting. Avoid placing ducts near trees or large plants. Roots can disrupt the installation over time.

Visibility is essential. The site should allow easy access for maintenance. Ensure there’s adequate space around your installation area. Complicated locations may lead to mistakes. Take time to finalize your layout before digging. Mapping out the installation can prevent unnecessary stress. Also, consider future expansions. It’s better to plan for growth now than face constraints later.

Make sure to comply with local regulations. Ignoring these can lead to unnecessary setbacks. Stay informed about underground utilities too. Digging in the wrong place can lead to accidents. This might seem straightforward, yet many overlook these factors. The proper planning can save time and resources later on.

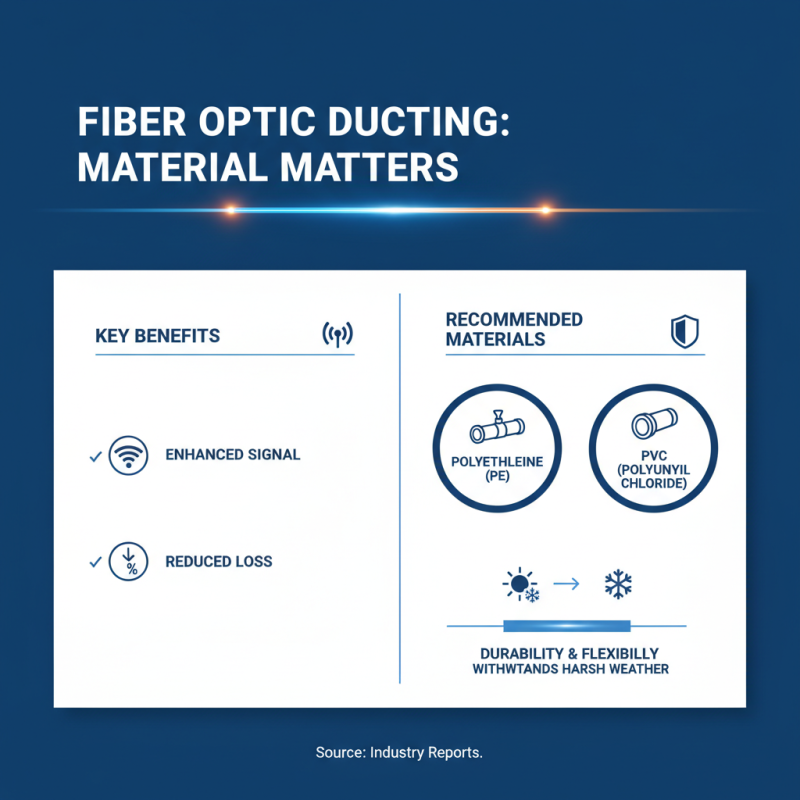

Selecting the Right Materials and Tools for Ducting Installation

When installing fibre optic ducting, choosing the right materials is crucial. High-quality ducting can enhance signal transmission and reduce loss rates. According to industry reports, using polyethylene or PVC for ducting can provide better durability and flexibility. These materials withstand harsh weather and avoid degradation over time.

Ensure your tools are appropriate for the job. A fibre optic installation setup typically requires cable pulls, markers, and duct end caps. Additionally, using a fibre optic fusion splicer can yield stronger connections. Remember that improper tools can lead to installation errors, affecting performance.

Tip: Always check for compatibility between the cable and the ducting materials. Mismatched components can result in increased signal loss.

Don’t overlook local regulations regarding installation. Compliance can prevent future issues and ensure optimal performance of the fibre optic network. Engaging with professionals for insights can be beneficial, but skill gaps may still emerge. Regular training and workshops can help fill those voids. Adapting to new technologies is essential for success in this evolving field.

Step-by-Step Guide to Installing Fibre Optic Ducting

Installing fibre optic ducting requires careful planning and execution. Ensuring optimal performance starts with choosing the right materials. The ducting must be weatherproof and durable, as environmental factors can affect signal quality. According to industry reports, poorly installed ducting can lead to signal losses up to 25%.

Begin your installation by mapping out the route. Use a shovel or trenching machine to create a trench, making sure it is deep enough, usually around 18 inches. Lay the ducting carefully to prevent kinks.

Tip: Always check local regulations before installation. This can save time and costs related to compliance issues.

After laying the duct, backfill the trench carefully. Avoid compacting too tightly as this can damage the duct. The temperature can also affect the flexibility of the materials.

Tip: Monitor the weather before installation. Extremely cold or wet conditions can complicate the process. Remember, each installation is unique. Reflect on what works and what doesn’t, adjusting your methods as needed.

Fibre Optic Ducting Performance Overview

This chart illustrates the relationship between fibre optic ducting installation quality and the resulting performance metrics such as data transmission speed and signal loss.

Testing and Maintenance Tips for Optimal Ducting Performance

When it comes to fibre optic ducting, testing and maintenance are essential for optimal performance. Regular audits can make a significant difference. According to industry reports, over 30% of ducting issues stem from improper installation or maintenance. Monitoring these systems can prevent costly downtime and signal loss.

Tips: Always check for physical damage to ducts. Small cracks can lead to significant signal degradation. Use specialized inspection tools to assess the integrity. Maintain a clean environment around the ducting. Dust and debris can build up and compromise the functionality.

It’s also crucial to perform regular performance tests. Schedule assessments every six months to ensure efficiency. Data shows that consistent testing improves lifespan by up to 25%. If you notice fluctuating signal levels, it is time to investigate. Simple adjustments can restore performance levels. Ensure workers are trained in both installation and troubleshooting to minimize errors.

Related Posts

-

Exploring the Benefits of Underground Ducting for Fibre Optic Cable Installation

-

The Future of Connectivity How Fibre Optic Network Cable is Transforming Communication

-

Top 7 Benefits of Using Underground Ducting for Fibre Optic Cable Installation Efficiency

-

How to Choose the Best Telecom Fibre for Your Home or Business Needs

-

Top 10 Tips for Choosing the Best Fibre Optic Internet Service

-

2026 Top Trends in Underground Fibre Optic Cable Technology?