How to Choose the Best Low Friction Cable for Your Needs?

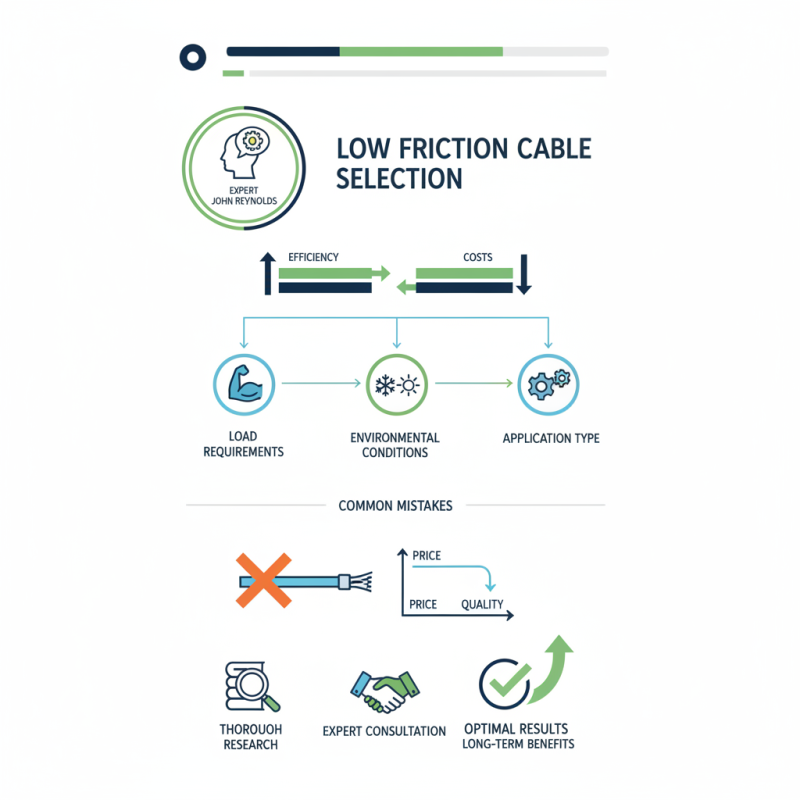

Choosing the right low friction cable is essential for enhancing performance in various applications. Expert John Reynolds, a leading authority in the cable industry, once stated, "Selecting the correct low friction cable can drastically improve efficiency." Understanding the specific needs of your project is crucial in making this selection.

There are many types of low friction cables available. Each type has unique characteristics and benefits. For instance, some cables minimize wear and tear, while others excel in reducing friction in tight spaces. The right choice hinges on factors such as load requirements and environmental conditions. Mistakes in selection can lead to reduced efficiency and increased costs.

Many users overlook important details when choosing low friction cables. They may prioritize price over quality or fail to consider application-specific requirements. This oversight can have critical consequences. Therefore, thorough research and expert consultation are vital for achieving optimal results. Investing time in understanding your options will pay off in the long run.

Understanding Low Friction Cables: Definition and Importance

Low friction cables are essential in various applications, from machinery to everyday devices. They are designed to minimize resistance and facilitate smoother operation. This reduction in friction can lead to improved efficiency and less wear on components. Understanding low friction cables is crucial to making informed decisions in their selection.

When choosing a low friction cable, consider the materials used. Different materials will have varying levels of friction and durability. It’s important to evaluate your specific application to determine what’s best. Pay attention to the cable's flexibility and strength as well. A strong, yet flexible cable can make a significant difference in performance.

Tips: Always measure the space where the cable will be installed. A cable that is too short or too long can cause issues. Test the cable's movement in different conditions. This will help you understand how it behaves in real-world situations. Be open to different types of coatings as well; they can significantly impact friction levels. Not every coated cable will work as you expect. Recognizing this can save time and effort in the long run.

Key Factors to Consider When Selecting Low Friction Cables

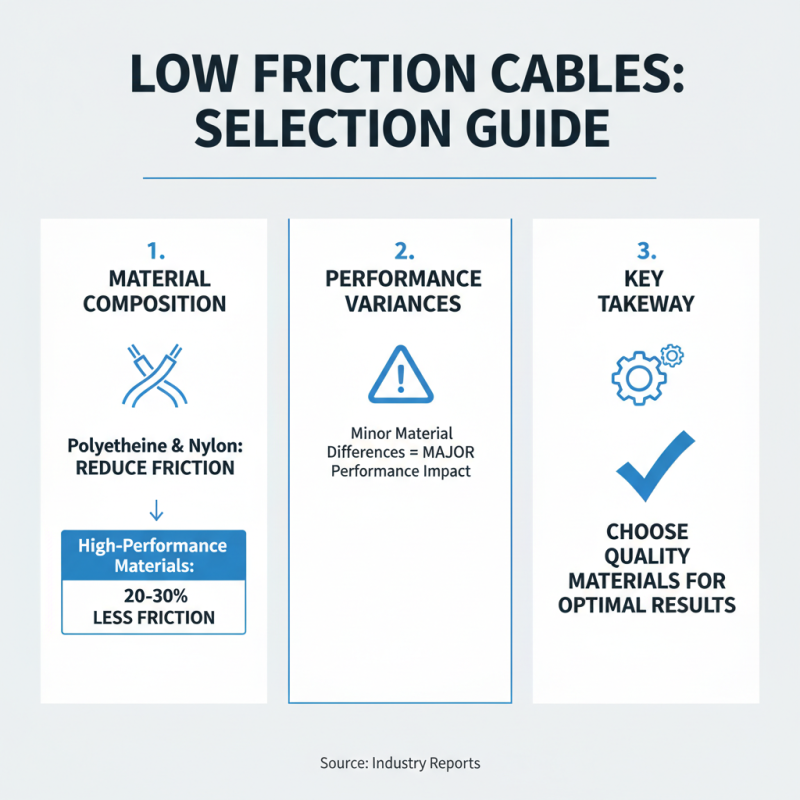

When selecting low friction cables, key factors come into play. One critical aspect is the material composition. Materials like polyethylene or nylon can greatly reduce friction. Reports suggest that high-performance materials can decrease friction by 20-30%. However, not all cables are created equal. Sometimes, seemingly minor differences in material can lead to significant performance variances.

Another factor to consider is the cable diameter. A thicker cable can improve durability but may also increase friction on bends. It's essential to balance these attributes based on the intended application. For instance, tight bends in a cable assembly can amplify friction, making a smaller diameter more appropriate in such cases.

Lastly, the application environment plays a vital role. Exposure to certain chemicals or temperature extremes can affect the cable's friction characteristics. Data from industry studies indicate that cables exposed to high temperatures may lose their low friction properties over time. In such situations, re-evaluating your choice becomes necessary. Thus, understanding these factors is crucial in ensuring optimal performance and longevity of low friction cables.

Industry Standards and Specifications for Low Friction Cables

Selecting a low friction cable requires understanding industry standards and specifications. These guidelines help ensure safety and performance. For example, the International Organization for Standardization (ISO) specifies a maximum coefficient of friction of 0.1 for low friction cables used in various applications. This standard is critical to reduce wear and tear, enhancing cable longevity.

Another important specification is the tensile strength required. A report by the American Society for Testing and Materials (ASTM) indicates that cables should have a minimum tensile strength of 1,200 N/mm² for effective operation in high-stress environments. Many manufacturers strive to meet or exceed this benchmark, but discrepancies sometimes arise. Quality control measures can fail, leading to subpar products in the market.

Moreover, abrasion resistance is vital. Cables exposed to harsh environments must withstand wear, often tested through specific abrasion methods. A study revealed that 30% of cables underperformed in real-world scenarios, failing to meet the claimed resistance. This highlights the importance of thorough testing and validation. Inspecting cables regularly ensures they adhere to relevant standards and specifications.

How to Choose the Best Low Friction Cable for Your Needs?

| Specification | Value | Notes |

|---|---|---|

| Cable Material | Polyester, Nylon | Durability and flexibility are key. |

| Coating Type | PTFE, UHMWPE | Provides low friction and reduces wear. |

| Diameter Range | 1 mm to 10 mm | Select based on application requirements. |

| Bending Radius | 3-5x diameter | Critical for installation and performance. |

| Temperature Range | -40°C to 100°C | Ensure it meets environmental conditions. |

| Lubrication | Self-lubricating options available | Reduces maintenance and extends life. |

Comparing Material Types for Optimal Low Friction Performance

When selecting a low friction cable, material choice plays a critical role. Different materials yield varying friction coefficients, which impact performance. According to a 2021 industry report, nylon cables exhibit a low static friction coefficient of around 0.15. In contrast, polyethylene options can lower this to approximately 0.10. While these numbers sound ideal, the durability of nylon in harsh conditions often makes it a preferred choice.

Metal cables may offer strength but can have higher friction. For example, steel cables often reach a friction coefficient of 0.30 or higher. This raised friction can lead to increased wear on other components. It’s essential to consider application context. A smooth operation in one environment might lead to issues such as excessive heat or breakage in another.

While many manufacturers recommend certain materials, it’s worth questioning whether these suggestions align with your specific needs. Are they focusing on performance and not considering the long-term costs? Moreover, what about the environmental impact of production? Balancing performance, cost, and sustainability can be challenging but necessary for informed decisions.

Applications and Use Cases for Low Friction Cables in Various Industries

Low friction cables play a crucial role in various industries, from manufacturing to aerospace. These cables reduce resistance and enhance performance, making them ideal for applications requiring smooth operation. For example, in automation, they improve the efficiency of conveyor systems. In healthcare, they enable precise movements in robotic surgical instruments. Each application benefits from the unique properties of low friction cables.

When selecting a low friction cable, consider the environment. Cables in extreme temperatures may need special coatings. Understand the load requirements. Overloading can damage cables, leading to unexpected failures. Testing is key.

Tip: Always conduct a thorough test of the cable in its intended application. This helps identify any potential issues early.

Cables used in marine applications must resist corrosion. In contrast, those in entertainment require flexibility. Analyze specific needs carefully for the best results.

Tip: Consult with experts to ensure you choose the right materials and specifications. Not paying attention to detail can lead to costly errors down the line.

Related Posts

-

10 Essential Tips for Installing Fibre Optic Ducting Like a Pro

-

What is a Network Cable and How Does It Work?

-

Understanding Drop Cable Types: A Comprehensive Guide for Fiber Optic Solutions

-

Exploring the Future of Connectivity with Aerial Fibre Cable Technology

-

Top 7 Benefits of Using Underground Ducting for Fibre Optic Cable Installation Efficiency

-

The Ultimate Guide to Choosing the Best Fibre Optic Cable Ducting Solutions